Paint

Prepainted metal is galvanized steel or aluminum which is painted by coil coating in a continuous and automated process before fabrication.In this process, a coil of galvanized steel or aluminum is first unwound and generally,both sides of the metal are cleaned.

Oil and other contaminants are removed from the metal. Then the metal surface is chromed in preparation for painting.Before painting, a coat of primer is usually applied on both sides and the primed metal is then sent to an oven for curing. After oven curing, the metal is cooled, a top coat is applied and the fully painted metal is again oven cured,cooled and rewound. The top coat color is selected from the RAL Standard color catalogue.

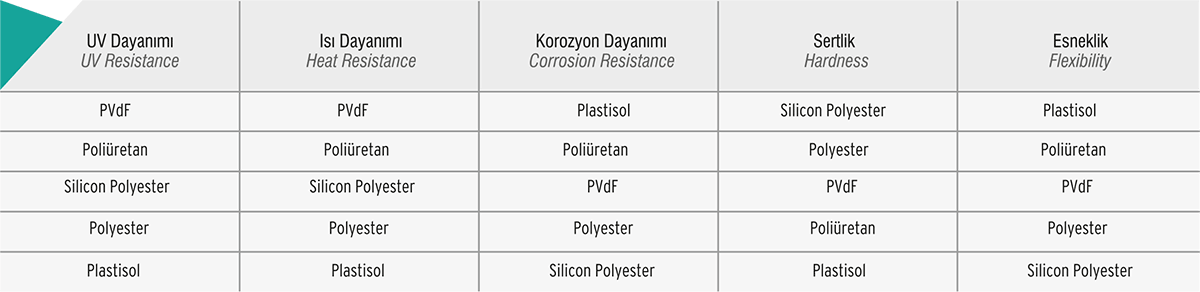

With coil coating process, a uniform coating thickness can be maintained. As for the top coating,after an epoxy primer is applied, a polyester, polyvinylidene fluoride (PVDF), plastisol or polyurethane resin is used, considering the requirements for geographical location and environmental conditions. Although, each of these coatings have different material properties, they all are used as liquid. In Turkey, the use of 5 micron primer and 20 micron polyester resin as a top coat, is generally accepted as sufficient. Painting assures much longer life span for metals and therefore, it is a cost-effective application. Coil coated metals can easily be bent or formed as required without any damage to coated surfaces.

In Europe, the life expectancy of coil coated metals, in areas with normal environmental conditions, ie., at inland locations away from the sea and locations with no air pollution concerns, is approximately 10 years. With a scheduled maintenance program, this duration can be increased to 40 years or even higher

There are some benefits using coated steel with an epoxy primer. Epoxy primer provides a strong bond between galvanized steel and insulation core or insulation adhesive material if used, and therefore, a more structurally sound, insulated composite section panel is created. Since a primer is not applied to the insulation side face of stocco embossed aluminum sheets, a good adherence between insulation core and aluminum sheet can not be obtained and a separation occurs between the two layer.